Reorder Level: The minimum quantity of a product that must be on hand. Inventory Value: This simply multiplies the stock quantity by the cost per item to arrive at the total value of the parts you have in your inventory. Stock Quantity: The total number of units of a part that you currently have in stock. Cost per Item: This calculates the exact amount of money you paid to the manufacturer for a single part. Description: Going into even more depth than the name or item number, the description tells you about the part’s physical characteristics. Naming them here helps you know who to contact when reordering. Manufacturer: The company you obtain a part from is known as the manufacturer, vendor, or supplier. Name: In addition to the item number, the item name more clearly tells you what the item is, such as a garden hose or a food ingredient. Item Number: A useful identification number you can attach to each part to keep everything distinct and easily identifiable when counting and reordering inventory. If you have plenty in stock, it will remain at the default of ‘OK’.

Reorder (auto-fill): If you get to the minimum inventory quantity for an item, this will tell you that it is time to reorder it.

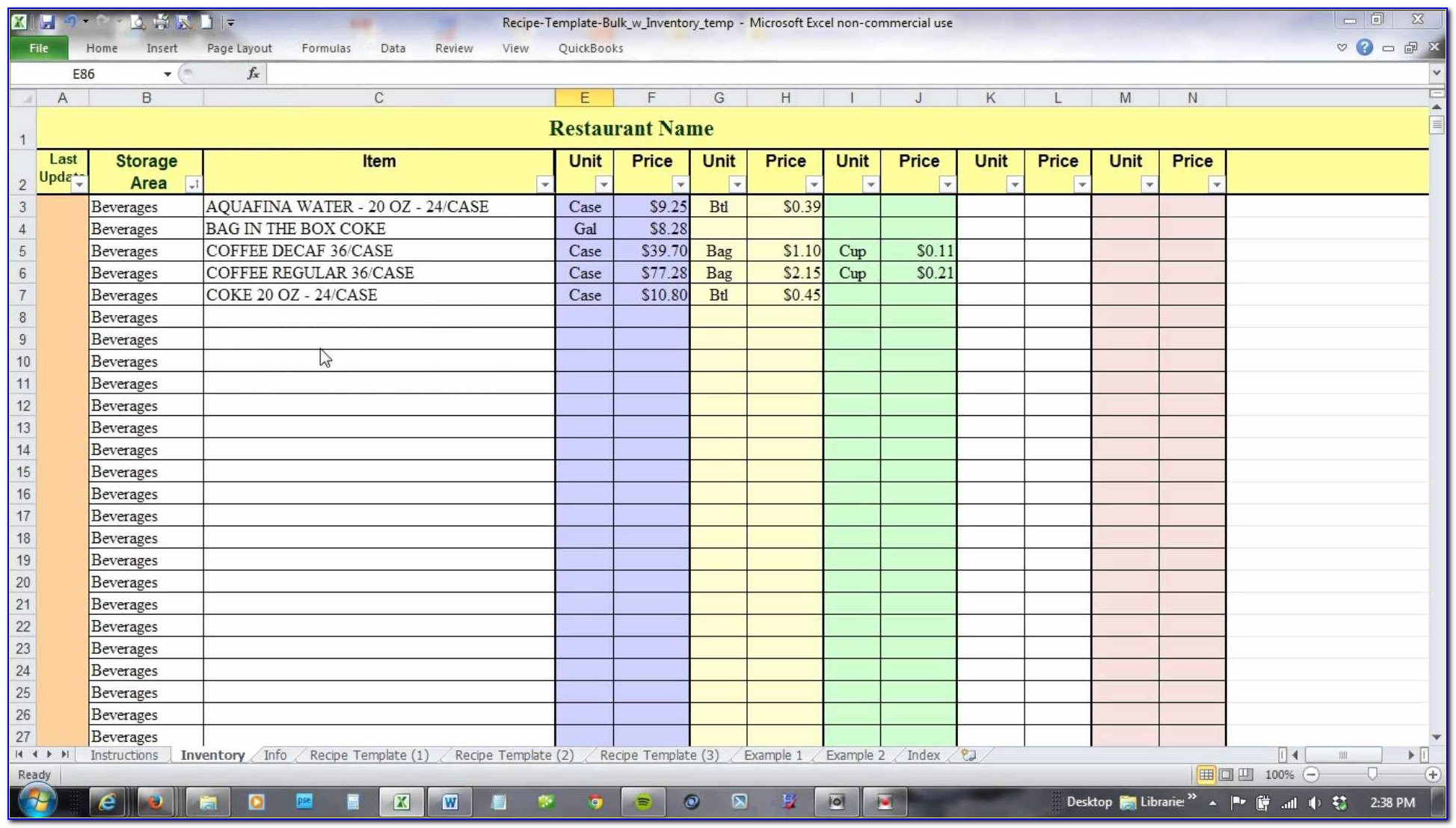

When you fill out the form and open the Excel spreadsheet, you will find it auto-populated with the following column headers: That is why Boxstorm offers this helpful inventory template to ensure you have what you need to get organized. It is not easy to go from no organization to a complex inventory management system. Boxstorm offers this Excel template to help you get started with managing your inventory.

0 kommentar(er)

0 kommentar(er)